Cutting Technologies

Modular and high-performance solutions to optimize precision, efficiency, and productivity on an industrial scale.

Precision, reliability, and efficiency are the cornerstones of our technologies, designed to optimize production processes and ensure the highest level of innovation.

Why choose us?

Benefits of our solutions

Versatility

A variety of cutting technologies and accessories makes our machines suitable for countless applications.

Modular structure

Our machines feature customized configurations and sizes to meet our customers needs and significantly enhance their production potential

Cutting Technologies

Our machines

Cutting Types

What is the ideal cutting technology for your needs?

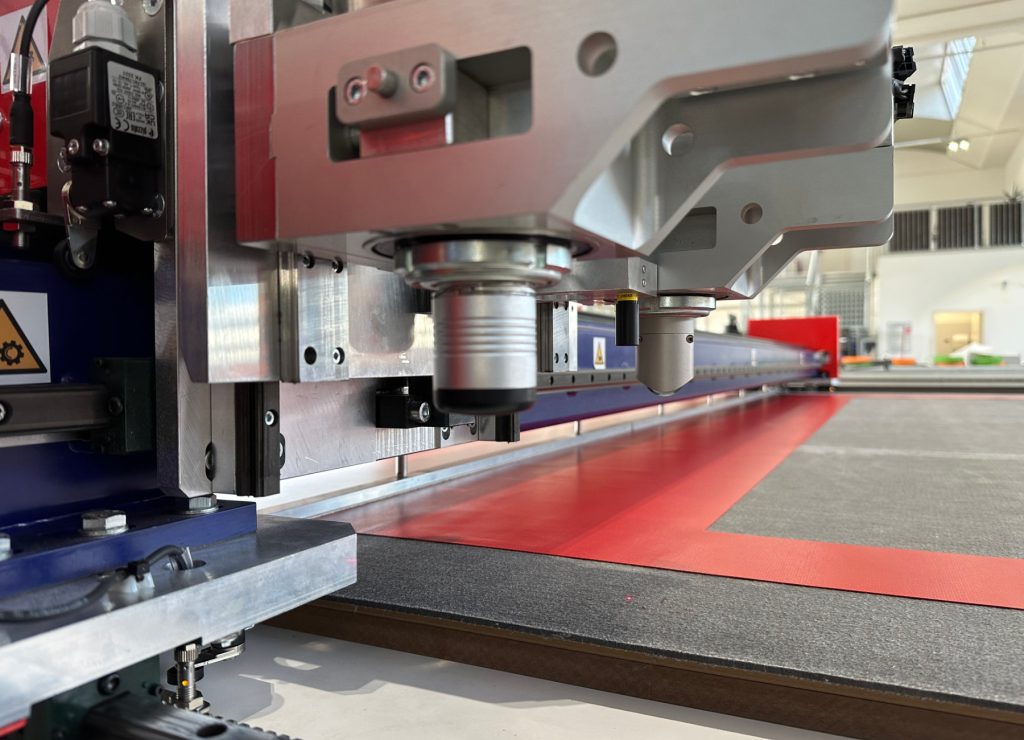

Blade Cutting

Our blade cutting machines are the ideal solution for working with soft or semi-rigid fabrics and materials without affecting their properties. Thanks to cold cutting technology, the material edges remain intact, avoiding the thermal alterations typical of other technologies like laser or ultrasonic cutting.

We offer cutting plotters with static or conveyorized beds and X-Y cutting tables, designed to ensure precision and productivity. The tools mounted on the bridge fit a wide range of applications, allowing for customized configurations to meet every cutting need.

Available Cutting Technologies

- Drag knife: Ideal for intricate details and precise cuts.

- Oscillating Blade: Perfect for thick and rigid materials.

- Rotary Blade (motorized or non-motorized): For fast cuts and simple shapes.

- Kiss-cut: For partial cuts on multi-layer materials, such as adhesives.

- V-Cut and Oscillating Blade: For angled cuts, useful for folding thick materials.

- Router: For 2D and 3D designs on rigid materials like wood or Forex.

- Punching Tool: For fast and precise hole punching.

Laser Cutting

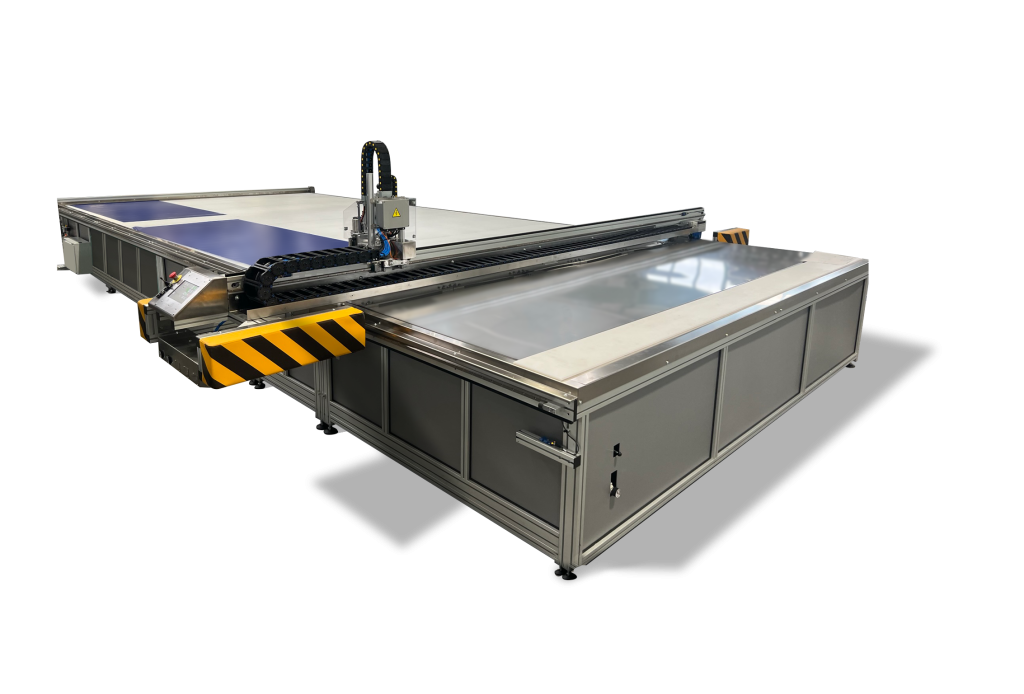

Our laser cutting plotters offer advanced solutions for working with different fabrics, including technical and rigid materials. This technology is ideal for industries such as sun protection, thanks to its ability to deliver clean, finished cuts, especially needed for sensitive and light-colored materials.

The laser beam does not physically touch materials, allowing for great precision, even on complex shapes. There are two types of laser cutting available:

- CO2 Laser Head: Reproduces CAD designs for precise and detailed cuts.

- Galvanometric Laser Head: Uses mirrors to create patterns on a limited area with extremely high speed and precision.

Modular Design

Our laser cutting machines stand out for their modular design and customizable options, allowing them to adapt to any production need. Available with a CO2 laser source up to 500W, machines can be equipped with either static surfaces or steel mesh conveyor belts.

In Detail

They are designed to perform highly precise cuts on complex shapes, permanently mark fabrics gently, and make high-speed micro-perforations. Each machine is also equipped with an integrated smoke collector, compatible with the customer’s suction system, to ensure a safe and efficient working environment.

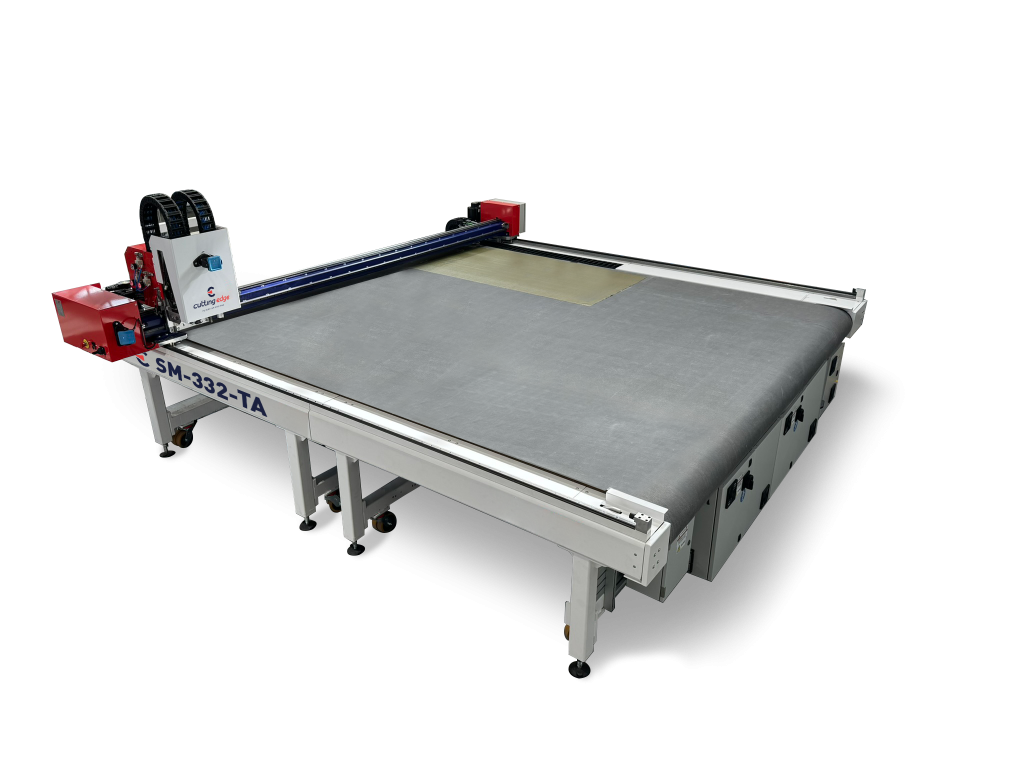

Ultrasonic Cutting

Ultrasonic Cutting: Thermal Precision for Synthetic Materials

Ultrasonic cutting is a thermal technology that uses high-frequency vibrations (40 kHz) to cut and cauterize the edges of materials during the process. This technique guarantees clean and precise cuts, particularly suitable for materials like acrylics, polyesters, and screen fabrics used in sun protection systems.

Our machines offer various processing options

- SM-375-TA and SM-400-TA: Ideal for parallel cuts along the machine’s axes (rectangular X-Y cuts).

- SM-332-TA: Designed for more complex cuts, including diagonal cuts, curves, and intricate shapes, thanks to an advanced ultrasonic tool.

Our ultrasonic cutting machines are available with either fixed or conveyorized work surfaces and can be equipped with additional tools to meet the most specific production needs.</p

What you can cut with our machines

Keder

Truck tarps

Pergolas

Pool covers

Industrial doors

Shade Sails

Tension structures

Advertisement Banners

Composites

Roller blinds

Custom mosquito nets

Inflatables

Awnings

Gazebo

Keder

Truck tarps

Pergolas

Pool covers

Industrial doors

Shade Sails

Tension structures

Advertisement Banners

Talk to an expert and discover the perfect solution for your company

Fill out the form to send us your request

Contact us on Whatsapp

+39 345 15 33 446

Why choose us?